Why Choose CDbF Connectors?

Why Choose CDBF connector ?

The reason to choose CDBF connector is to achieve reliable, secure, and efficient connections in bad environments,For example : in dust ,humid or harsh industry environment etc.

Following are some advantages of Using Cdbf Connectors:

1. High Reliability and Durability

Solid Design: with Metal housing (like zinc die-cast) and high-performance engineering plastic, it can undertake high shock, vibration, and stress etc. It can use in Aerospace industry.

High protection Grade: Their protection Grade can reach to IP65/IP66/IP67 (dustproof and waterproof) or higher, which make they work reliably in dusty, humid, and even temporarily submerged application.

High Environmental Resistance: with Excellent resistance to chemicals, oils, and UV rays (for outdoor use), and a wide operating temperature range (e.g., -40°C to +125°C), they can work well.

- Excellent Electrical Performance

High Voltage/urrent Capacity: Cdbf connectors can carry currents ranging from signal levels to hundreds of amperes and voltages up to thousands of volts, meeting a wide range of demand of control circuits to high-power transmission. It can work in Vehicle device.

Excellent Shielding: Cdbf connector can supply 360° shielding, they resist electromagnetic interference (EMI) and radio frequency interference (RFI), which is important to secure the integrity of data transmission. This make it stablely used in Network Scenario.

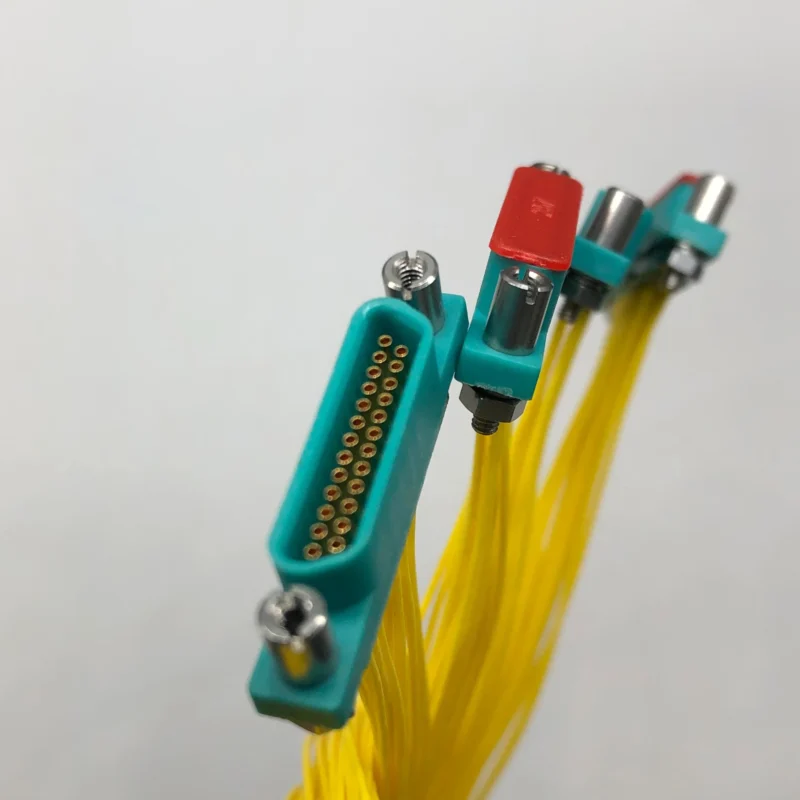

3. Flexibility and Modular Design

It is one of their core advantages. A single CDBF connector housing can connect with lots modules with functions.

E.g. Power Module: Transmitting Power.

Signal OR Data Module: Transmitting signal or data (e.g., RJ45, USB, fiber optic or coaxial cables).

Pneumatic Module: Transmitting compressed air (fluid).

Saving Space and Cost : Through modular design, power, signal, and data can be integrated into a single connector, it reduce wiring time, and simplify device design.

4.Safety and Ease Use.

Anti-mating and Coding: Cdbf connector provide Various mechanical coding methods , which are available to ensure that different connectors cannot be mis-mated, preventing equipment from damage or any safety incidents.

Locking Mechanism: With Reliable locking mechanisms (such as screws, snaps, and levers), Cdbf connector ensure all connection will not loosen or fall off even in vibrating environments.

Long Mating and Removal Cycle Life: Connectors have Special Design for frequent mating and removal, ,which ensuring a long service life.

Easy Field Wiring: Many models apply with cage clamp technology or screw connections for fast, reliable wiring without special tools.

Summary: When would we choose this type of connector?

Cdbf connector should be best choice when your application meets one or more of the following Scenario:

- Harsh environments: Such as dust, moisture, water splashes, oil, chemicals, or extreme temperatures.

- High mechanical stress: Scenario of strong vibration or shock.

- High reliability Request : Connection failures can lead to production downtime, safety incidents, or significant losses.

- Demand of Multiple media integration: Scenario of request to deal Power, signals, data, and even air pressure must be processed simultaneously at a single connection point.

- Scenario of Frequent plugging and unplugging : For example in automated production modules and AI robotic tool heads that require frequent replacement.

In short, the core reason to choose using CDBF connector is that they are not only “plugs-and-sockets” but “integrating-solutions” design ,which ensure stable, continuous, and safe usage in complex industry systems. While the cost may be higher than that of consumer connectors,but with reliability, production efficiency, and lower maintenance costs, they offer make the total cost of ownership (TCO) great advantages.