M8 vs M12 Connectors: Key Differences, Applications, and Selection Guide

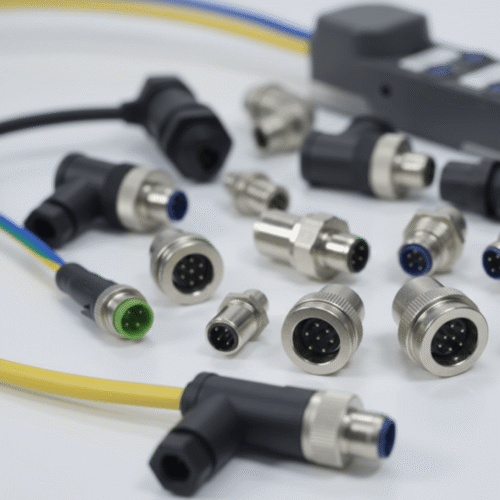

In modern industrial automation systems, metric circular connectors are crucial standardized interfaces for transmitting power and signals. M8 and M12 connectors are two popular types of metric circular connectors, widely used in sensors, actuators, and industrial networks.

However, there are also many differences between these two types of connectors. Understanding the differences between M8 and M12 connectors is crucial for choosing the right solution for your industrial applications. Next, we will explore the essential differences between these two major industrial connectors through a multi-dimensional comparison.

1. Introduction: Understanding M8 and M12 Connectors

Both M8 and M12 connectors belong to the metric circular connector category.

Metric circular connectors are cylindrical connectors that employ a metric threaded locking mechanism. These connectors primarily comply with international standards established by the IEC (International Electrotechnical Commission), such as their core standard IEC 61076-2 series. This is one of the most commonly used standards in the global industrial automation field.

Where M stands for threaded locking mechanism, the following number represents the thread diameter (unit: mm). For example, an M8 connector represents a thread diameter of 8 mm, and an M12 connector represents a thread diameter of 12 mm.

2. Key Differences Between M8 and M12

Although both M8 and M12 connectors are standardized metric circular connectors widely used in industrial automation, they differ significantly in size, electrical performance, and application range. Let’s explore these differences in more detail below.

| Parameter | M8 Connector | M12 Connector |

| Pin Counts | 3, 4, 5, 6, 8 poles | 2, 3, 4, 5, 6, 8, 12, 17 poles |

| Coding Types | A, B, D Coding | Signal: A, B Coding Data: D, X, Y Coding Power: S, T, K, L, M Coding |

| Rated Current | 1.5A to 3A | Signal: 1.5A / 2A / 4A Data: 0.5A / 6A / 12A Power: 8A / 12A / 16A |

| Rated Voltage | 30V/50 V/60V | Signal: 30V / 60V / 250V Data: 30V / 60V Power: 63V / 600V / 630V |

| Wire Gauge (AWG) | 22 AWG to 26 AWG | 18 AWG to 24 AWG (Up to 14 AWG for Power) |

| Ingress Protection | IP67 (Standard) | IP67, IP68, IP69K (Washdown environments) |

| Locking Mechanism | Threaded (M8 x 1.0) / Snap-lock | Threaded (M12 x 1.0) / Push-Pull Quick Lock |

2.1 Physical Dimensions

Size is the most obvious difference between M8 and M12 connectors.

M 8 connectors have an 8 mm thread diameter and a compact design. They are often used in applications with extremely limited installation space, such as small sensors.

M 12 connectors, on the other hand, have a 12 mm thread diameter, making them larger and heavier than M 8 connectors, and capable of withstanding greater mechanical stress and mating cycles.

2.2 Pin Count & Coding

The pin configurations and coding rules of M8 and M12 connectors differ significantly.

Generally, M8 connectors have 3, 4, 5, 6, and 8 pin configurations. Their coding rule primarily uses Type A coding, which is currently the most common coding rule for M8 connectors. Other coding rules include B-Coding and P-Coding.

M12 connectors offer a wider range of pin options, up to 17 pins, and a more comprehensive encoding system, including A, B, D, and X encodings, as well as X-type and S/T/K/L-type power encodings. They accommodate various transmission needs, including signal, data, and power transmission.

2.3 Electrical Performance

In terms of electrical performance, the current carrying capacity of M8 connectors is typically limited to 1.5A to 3A, and they are mostly used in low-voltage systems of 30V to 60V. As for M12 connectors, the signal-coded version can carry up to 4A, while the power-coded version supports up to 12A to 16A. The M12 power type can carry up to 630V, making it suitable for high-voltage applications.

2.4 Data Transfer Rates

If you require high-speed data feedback, the M12 is the only option. While the M8 can also transmit basic data, the M12 X-Coding is currently the mainstream solution for achieving 10 Gigabit (10Gbps) transmission in industrial Ethernet.

2.5 Environmental Resistance

Both M8 and m12 connectors offer high protection levels, but the specific rating depends on the design.

Both M8 and M12 connectors offer protection ratings of IP67 (dustproof, short-term immersion) or IP68 (continuous immersion). However, due to its smaller size, the M12 connector is more likely to achieve higher sealing ratings such as IP69K (high pressure, high-temperature water immersion).

Both connectors are available with various housing materials, including plastic (PUR, PVC) and metal (nickel-plated brass, stainless steel).

2.6 Application Scenarios and Market Positioning

M8: Designed for space-constrained applications. Commonly used for small sensors (photoelectric, proximity switches), miniature actuators, and narrow machine internal connections.

M12: Designed for high-performance, multi-functional, and standardized applications. It forms the physical layer backbone of industrial communication networks (Ethernet, fieldbus), used to connect the vast majority of industrial devices.

3. Typical Applications of M8 and M12 Connectors

| Parameter | M8 Connector | M12 Connector |

| Typical Applications | • Miniature photoelectric sensors and capacitive/inductive proximity switches • Compact instrumentation • Internal wiring for lightweight robotic arms • Weight- and space-sensitive equipment | •Industrial networking •Standard sensors and actuators •Valve islands and pneumatic manifolds •Fieldbus systems •Harsh environment equipment |

4. When to Choose M8 Connector

If you need a connector that meets the following requirements:

– Extremely limited installation space, unable to accommodate an M12 connector;

-High requirements for lightweight equipment, necessitating reduced wiring density;

– Only low-power signals or simple sensor/actuator commands need to be transmitted;

-Rated current and voltage requirements (≤3A, ≤60V)

Then the M8 connector, with its compact, lightweight, and flexible installation advantages, performs exceptionally well in distributed systems and micro-devices, making it the ideal choice for achieving reliable connections in confined spaces.

5. When to Choose M12 Connector

When to choose an M12 connector?

If you need connectors for:

-Transmitting higher power or higher speed data (such as industrial Ethernet);

-Supporting complex signal combinations with multiple pins and codes;

-Environments subject to harsh conditions such as vibration, humidity, oil contamination, and high-temperature washing;

-Devices that are compatible with mainstream industrial network standards and have future expansion capabilities;

M12 connectors, with their high modularity, rich coding system, and excellent adaptability to harsh environments, have become the first choice for complex automation systems. They are particularly suitable for scenarios that require the simultaneous transmission of power, signals, and data.

6. Conclusion

In summary, both M8 and M12 connectors play important roles in industrial automation, but they are designed for different priorities and use cases.

M8 connectors stand out for their compact size, light weight, and ease of installation. They are an excellent choice for applications where space is limited and only low-power signals or simple sensor/actuator connections are required. In decentralized systems and compact devices, M8 connectors help reduce wiring density while maintaining reliable performance.

M12 connectors, on the other hand, offer greater versatility and robustness. With higher pin counts, a wider range of coding options, and support for higher power and data transmission—including industrial Ethernet—they are well suited for complex automation systems. Their availability in higher IP protection levels also makes M12 connectors a preferred solution for harsh industrial environments involving moisture, vibration, or frequent washdowns.

By clearly understanding the differences in size, electrical capability, coding, environmental protection, and application scope, engineers and system designers can make more informed connector choices. Selecting the right connector not only improves system reliability and scalability, but also helps optimize installation efficiency and long-term maintenance costs.

If you have any questions about selecting M8 Connectors, and M12 Connectors, or other M series connectors, please feel free to contact us. As a professional connector manufacturer with 20 years of production experience, HuaDa Group can provide you with professional selection guidance and advice.