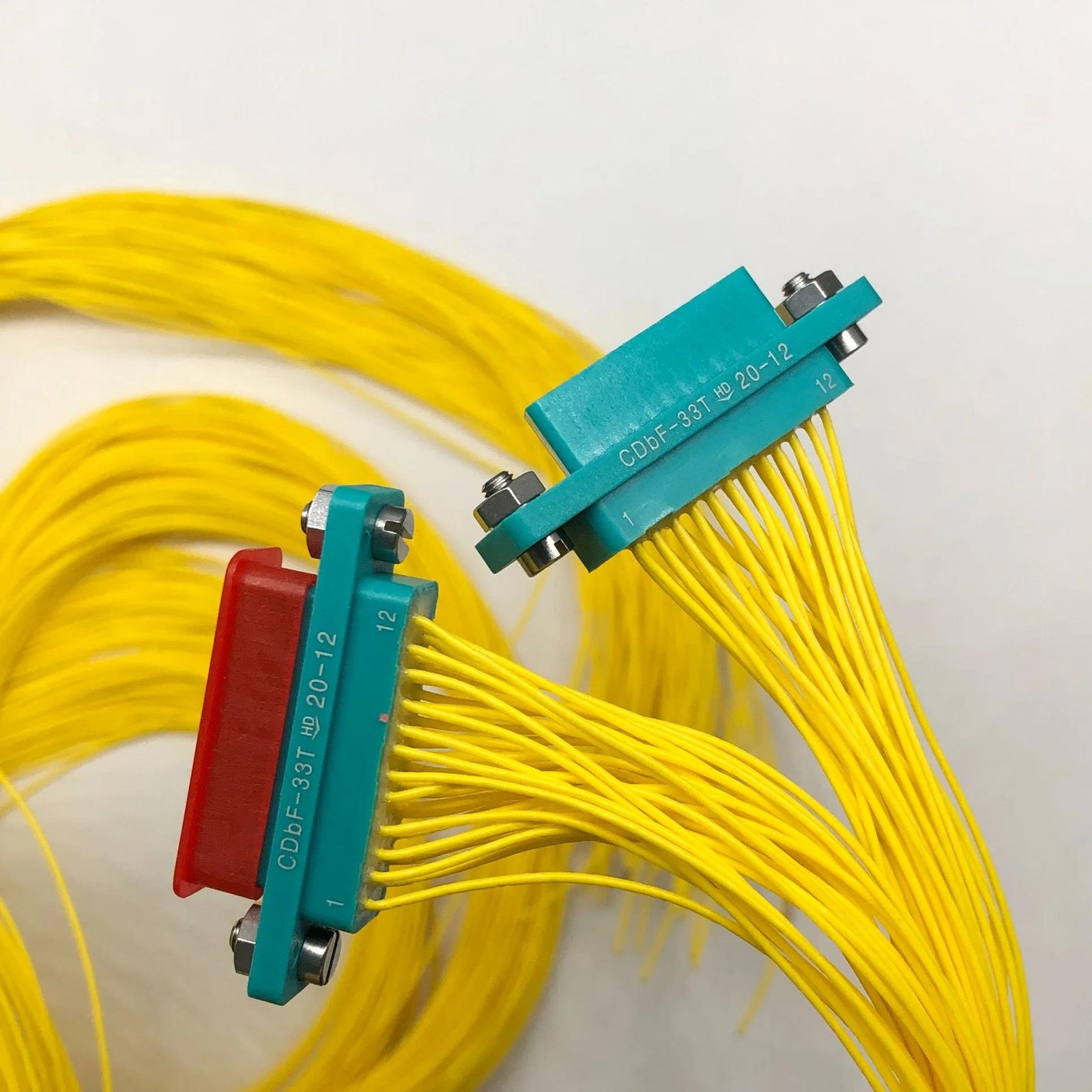

CDbF Series Micro-Rectangular Electrical Connector 33Pins/Sockets 50cm length wire CDbF-33Z-50CM CDbF-33T-50CM

CDbF Series Micro-Rectangular Electrical Connector 33Pins/Sockets 50cm length wire CDbF-33Z-50CM CDbF-33T-50CM

CDbF Series Micro-Rectangular Electrical Connectors

● Number of Pins/Sockets: 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16

● Pin/Socket Pitch: 1.27 mm, Single Row

● Crimping cross-sectional area of Wires: 0.05 mm² to 0.15 mm²

● Detailed Specification Implemented: 0/MB20604-2018

- sales@connector-sensor.com

- +86 15120067961

- cable assembly4 products

- Cable assemblies for locomotives4 products

- Cable assemblies for petroleum equipment manufacturing4 products

- Flexible Printed Circuit Cable Assemblies4 products

- High temperature and flame resistant cable assemblies4 products

- High-speed transmission cable assemblies4 products

- Mining cable assemblies4 products

- RF cable assemblies4 products

- Vulcanized cable assemblies4 products

- connector63 products

- Aerospace connectors4 products

- Circular electrical connector4 products

- Dropped connector4 products

- Glass sintered seal products4 products

- High-speed data transmission series connector4 products

- Rectangular and micro rectangular connectors4 products

- Rectangular Connector59 products

- RF connector4 products

- electronic control device4 products

- Motor series4 products

- Optoelectronic devices and equipment4 products

- relay4 products

- Smart manufacturing4 products

The CDBF series electrical connectors are high-reliability interconnection solutions specifically engineered for industrial automation, aerospace, energy, transportation, and military applications. Renowned for their exceptional environmental adaptability, mechanical robustness, and electrical performance, these connectors are the preferred choice for extreme operating conditions.

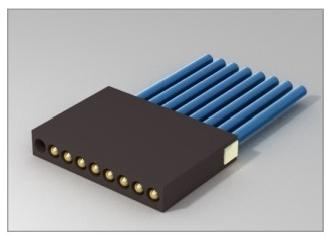

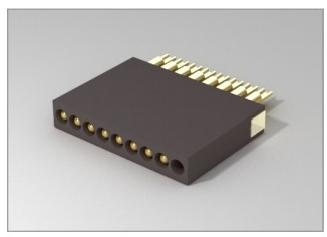

CDbF Series Micro-Rectangular Electrical Connectors

Number of PINs: 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16

Pin Pitch: 1.27 mm, Single Row

For use with wires having a crimping cross-sectional area: 0.05 mm² to 0.15 mm²

Detailed Specification Implemented: 0/MB20604-2018

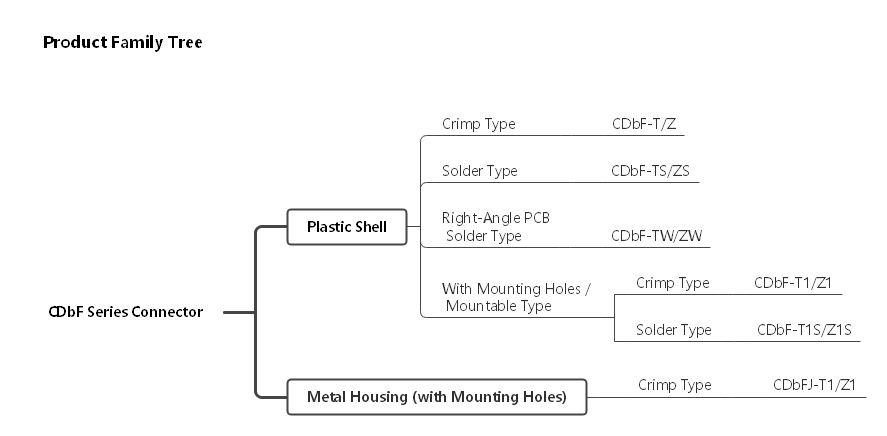

| CDbF Series Connector Model Designation Explanation | |||

| No. | Classification Features | Classification Content | Identification Code |

| 1 | Main Designation Code | Micro-Rectangular Connector | CDbF |

| 2 | Structural Typ | Plastic Shell | Not Indicated |

| Metal Shell | J | ||

| 3 | Number of Pins | Total Number | by Arabic Numerals |

| 4 | Type of Pins | Pin Contacts | T |

| Socket Contacts | Z | ||

| 5 | Mounting Method | With Mounting Holes | 1 |

| 6 | Termination Style | Crimped (with Wires) | Not Indicated |

| Soldered | S | ||

| Right-Angle PCB Solder | W | ||

| 7 | Modified Version | by Arabic Numerals | |

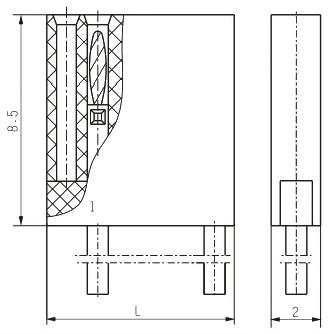

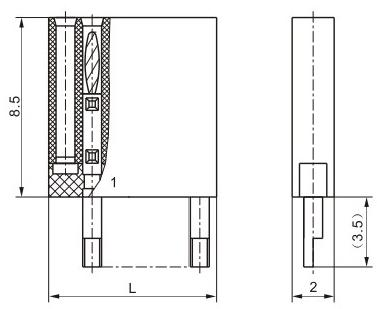

△ CDbF series plastic shell electrical connector

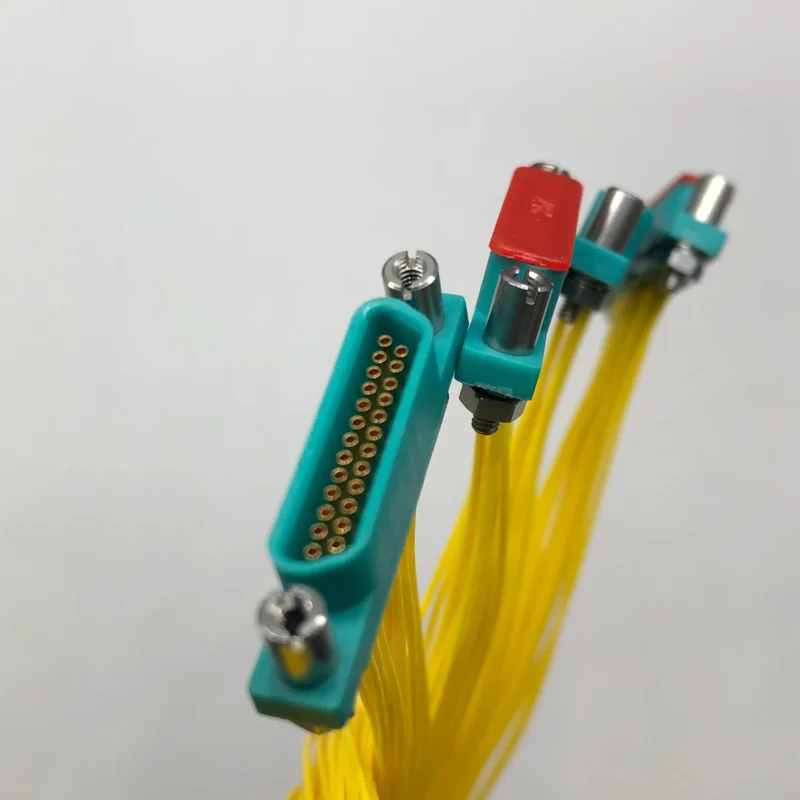

◎ CDbF crimping electrical connector

◎ CDbF welding type electrical connector

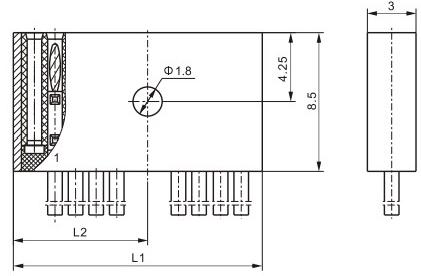

CDbF Series Metal Shell Electrical Connectors

CDbFJ Crimp Electrical Connectors with Mounting Holes

Send Message to get Datasheet.

Strict Production Process

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

High purity silica (usually quartz or sand) and carbon (usually petroleum coke or coal) are ground to produce fine powder.

Strict Production Process of Yafeite