Circular vs. Rectangular Connectors: What’s the Difference?

Circular 和 rectangular connectors are two commonly used types of electrical connectors. They are widely used in communication equipment, industrial automation, automotive electronics, and various electronic systems.

Although both circular and rectangular connectors support power, signal, and data transmission, they differ significantly in structural design, performance, and application environments. This article will explore their distinctions, serving as a useful reference whether you aim to deepen your understanding of the connectors or seek guidance for project selection or procurement.

Table of Contents

1. What is Circular Connector?

Circular connectors are electrical connectors with a cylindrical housing and multiple internal pins.

Their symmetrical circular structure allows for easy mating and provides 360° sealing, offering excellent waterproof and dustproof performance.

Circular connectors can be categorized into various types according to application standards, functional purposes, and locking mechanisms. This classification includes widely used M-series circular connectors (such as M 8 and M 12), MIL-Spec circular connectors, as well as specialized circular connectors designed for power, data, and fiber optic transmission, among others.

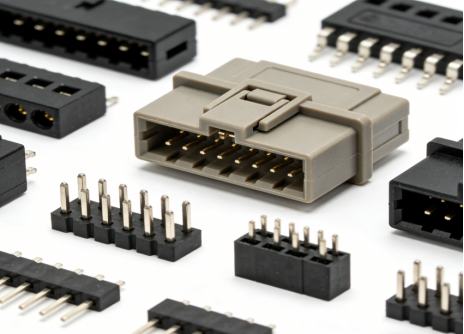

2. What is Rectangular Connector?

Rectangular connectors, as their name suggests, have a rectangular housing cross-section. Their contacts are typically arranged in multiple rows or a grid pattern, allowing for the integration of more contacts within a limited and compact space. By configuring different contact specifications within the same connector, rectangular connector can simultaneously support the transmission of multiple signals and power.

Common types of rectangular connectors include modular rectangular connectors, D-Sub connectors, PCB-mount rectangular connectors, 和 heavy-duty rectangular connectors. Data and I/O interfaces — such as R J 45, USB, 和 HDMI/Display Port – are often implemented in rectangular form factors. In high-reliability applications such as military, aerospace, and industrial automation, MIL -Spec rectangular connectors are often used.

3. Circular vs. Rectangular Connectors: Key Differences

As two mainstream types of electrical connectors, circular and rectangular connectors are often compared. However, the differences between them go beyond just their shape; there are also significant differences in performance, environmental adaptability, and typical applications.

Below, we will provide a comprehensive analysis of 8 different aspects.

3.1 Design and Structure

Circular connectors have a circular mating surface, with their contact pairs distributed around a central axis. This structure results in lower space utilization but offers better symmetry and sealing.

Due to the inherent mechanical stability of its circular design, circular connectors possess excellent resistance to vibration and shock. They possess inherent torque resistance, making them ideal for environments involving rotation or vibration.

Rectangular connectors, on the other hand, have their contact pairs enclosed within a rectangular interface housing with right-angled edges. Their contact pairs can be arranged in single, double, or multiple rows for high-density configurations.

This compact layout maximizes the use of valuable space on your panel, circuit board edge, or equipment enclosure.

3.2 Electrical and Mechanical Performance

Both circular and rectangular connectors offer excellent electrical and mechanical performance. Yet, their differing designs mean that each type excels in distinct areas, such as current carrying capacity and signal density.

| Typical Parameter | Circular Connector | 矩形连接器 |

| Contact Count Range | Typical: 2 – 104 contacts • Sensor-grade (M8/M12): 3-12 contacts • Military-grade: 7, 19, 37, 55, 104 contacts | Typical: 6 – 200+ contacts • D-Sub: 9-78 contacts • Modular Industrial: 48-200+ contacts |

| Contact Current Rating | Signal Contacts: 1 – 7.5A Power Contacts: • Standard: 10 – 40A • High-Power: 50 – 200A+ | Signal Contacts: 1 – 3A Power Modules: • Standard: 10 – 40A • High-Power: 63 – 200A+ |

| Typical Rated Voltage | Industrial Low Voltage: 30 – 250 V Medium / High Voltage & Military-grade: 500 – 3000 V+ | Signal / Low Voltage: 30 – 250 V Power / Medium-high Voltage: ≤ 1000 V |

| High-Frequency / Data Transmission Capability | Typical Applications:Industrial Networks • M12 D-coded: 100 Mbps • M12 X-coded: 10 Gbps • Specialty: ≤ 25 Gbps | Typical Application:High-Speed Protocols • USB 3.2 / USB 4: 20 / 40 Gbps • HDMI 2.1: 48 Gbps • QSFP-DD / OSFP: 400 / 800 Gbps • PCIe 5.0: 32 GT/s |

3.3 Locking and Mating Mechanisms

Common locking mechanisms for circular connectors primarily include the following three types:

- Threaded Coupling

- Bayonet Coupling

- Push-Pull Coupling

Depending on the specific design of the circular connector, you may need multiple rotations, limited angle rotations, or simply a push-pull action to complete the locking process during insertion and removal.

Although the operation may be slightly more complex, the connection is secure and offers excellent resistance to vibration and loosening.

Rectangular connectors typically use straight or side-entry mating methods and have a defined insertion and removal direction. Their typical locking mechanisms include:

- Screw Locking

- Snap-fit / Spring Latch

- Lever Lock/ Frame Lock

3.4 Ingress Protection and Environmental Resistance

Circular connectors generally offer a higher degree of protection than rectangular connectors. Typically, industrial circular connectors have an IP67 protection rating. With special design, this rating can even be increased to IP68 或 IP69K, making them ideal for use in harsh environments such as those with high humidity and dust.

In contrast, rectangular connectors commonly used inside equipment (such as board-to-board connectors and D-Sub connectors) typically have a basic protection rating of around IP20. Some heavy-duty rectangular connectors can achieve higher protection levels, such as IP65, IP67, or IP68, by adding sealed housings, but this is not achievable for all rectangular connector series.

3.5 Typical Applications

| Feature Aspect | Circular Connector | 矩形连接器 |

| Key Advantages | Excellent Sealing; Vibration Resistance; Environmental Adaptability; Robust Mechanical Strength; Easy Mating/Unmating; | High Space Utilization; Flexible Signal/Power Modularity; High-Speed Signal Integrity; High Pin Density; Cost-effective for Large-scale Systems; |

| 典型应用 | • Industrial Automation • Defense & Aerospace • Heavy Machinery & Agriculture • Automotive & Trucking • Renewable Energy • Oil, Gas & Mining Equipment • Professional Audio & Broadcast • Outdoor Security & Surveillance • Medical Devices • Test & Measurement | • Data Centers & Cloud Computing • Computing & Consumer Electronics • Industrial Control Cabinets • Advanced Medical Imaging • Defense Electronics • Semiconductor Manufacturing Equipment • Telecommunications Infrastructure • Automotive Electronics • Aerospace Systems • Scientific & Research Instruments |

3.6 Installation and Maintenance

In terms of installation and maintenance, circular and rectangular connectors require different approaches.

For circular connectors, ensuring proper sealing during installation is crucial. Align and tighten the snap-fit or threaded interface to guarantee a correct seal. Maintenance should focus on checking for aging or damage to the O-ring and cleaning the sealing surfaces to prevent dust or debris from affecting the sealing performance.

For rectangular connectors, ensuring precise alignment and a stable connection is very important during installation.

During installation, ensure that the pins and sockets are perfectly aligned to avoid bending or damaging the pins due to misalignment. Furthermore, during routine inspections, pay close attention to whether the cables are securely fastened, and check for loose or corroded internal terminals.

3.7 Customization and Modular Capability

The customization of circular connectors is mainly reflected in aspects such as their housing material, number and arrangement of contacts, coding method, locking mechanism, and cable exit method. Their modular capabilities are relatively limited, typically featuring a fixed pin configuration.

However, rectangular connectors usually support highly flexible selection and arrangement of internal modules, such as power modules, signal modules, and fiber optic modules. This is highly beneficial for system integration and subsequent expansion or upgrades.

3.8 Cost Considerations

The unit price of circular and rectangular connectors typically ranges from a few dollars to hundreds of dollars, depending on factors such as brand, specifications, and performance level.

Generally, circular connectors tend to have a higher unit price. This is mainly due to their more complex structural design, such as high-precision locking mechanisms in the metal casing, which provide superior sealing and vibration resistance. Rectangular connectors, on the other hand, usually offer a cost advantage in large systems or multi-functional integration projects.

4. Conclusion

Based on the above, you can see the main differences between circular and rectangular connectors. Both types can provide reliable and consistent performance if applied in the right situations. To choose the right connector, consider your specific needs, such as the operating environment, available space, installation preferences, future expansion, and overall cost. Keeping these factors in mind will help you find the best balance between performance and value.

With over twenty years of experience in connector design and manufacturing, Huada delivers high-performance circular 和 rectangular connectors at competitive prices, along with comprehensive one-stop interconnect solutions. Have questions or want more information? Feel free to contact us.